Obviously written communication with drawings plan and section is absolutely essential in order to ensure good detailing between our roof lanterns and the builder s supporting kerb upstand.

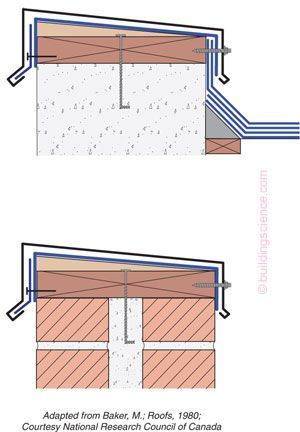

Roof lantern upstand detail.

Download technical drawings of our roof lanterns.

Screw a timber down around the hole approx 100mm high and 70 mm wide making sure the size of the hole does not change.

Components to be supplied by just roof lanterns.

Materials and works to be carried out by others.

This kerb is called an upstand the outside face of which allows the flat roofs external surfacing to lap up and form a weather tight junction.

All our roof lanterns shown on this website are designed to be fixed onto a kerb like detail which rises proud of the supporting flat roof assembly precisely at the open edge of the lantern aperture.

Components to be supplied by just roof lanterns.

Aluminium roof lantern cill plate.

Aluminium glass end closure.

Unit 8 rye harbour industrial estate rye harbour road rye east sussex tn31 7te.

Roof lantern cill plate.

Materials and works to be carried out by others.

Timber packer requirement depends upon kerb width.

100mm wide upstand frame constructed from 100mm x 50mm timber.

The upstand must be at least 150mm in height and should a minimum pitch of at least 3 degrees.

The job of an upstand sometimes referred to as a kerb is to lift the glass element of your rooflight off of the roof s surface and is required by building regulations for safety and weathering reasons.

Traditional lantern upstand detail how to do the timber to timber up stand set out the timbers on the flat roof leaving a hole where the roof lantern will be fitted and allowing enough room for spotlights if required.