The steady state thermal analysis shows the total isothermal r value for the wall with the ability to factor in thermal breaks such as metal ties or solid concrete sections.

R value of tilt up concrete wall.

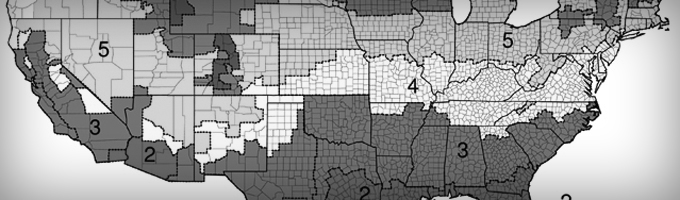

Jim baty with the tilt up concrete association tca provides an in depth review of tilt up wall panels compared to other building systems for new r value and u value requirements in a recent article in.

Tilt wall s len overbeek ranked one of the world s top 50 most influential tilt up professionals july 16 2020 comments off.

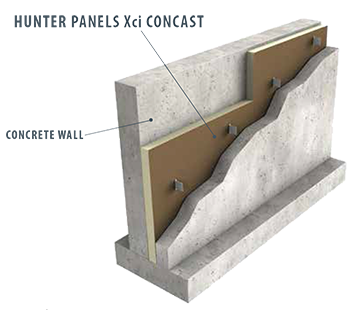

The insulating materials used for these systems range in r value.

However since it s easy to add insulation to any tilt up panel this number can rise substantially.

By placing 2 inches of extruded polystyrene within a tilt up panel as a sandwich panel the material r value of that wall is increased to 11 49 with air film coefficients of 0 85.

The r value of an uninsulated 8 inch thick basement wall built using normal weight concrete is 1 35 based on data from the 1993 american society of heating refrigeration and air conditioning engineers handbook.

With over 35 years of experience we are the undisputed leader in concrete sandwich wall technology and can help you create building envelopes that maximize energy efficiency durability and performance.

The standard r value of ready mix concrete used in the tilt up industry including the air film is 1 49 for an 8 inch wall panel.

Precast concrete construction is well known in the industry but tilt up concrete construction is the breakout method for constructing buildings of tomorrow.

You will notice in the findings shown in the isothermal analysis that the thermomass wall panel has a material r value of r 11 49.

By doubling the thickness of the wall to 16 inches the r value only increases by 0 50.

The 3 most common insulation methods for tilt up concrete construction.

Based on astm c518 calculation method the door has an r value of up to 11 but using astm c1363 tested operable the same door only have an r value of up to 3 5.

We manufacture and distribute a full line of concrete insulation systems for use in plant precast site cast tilt up and cast in place projects.

Download the document in pdf format 2 pages 214 kb astm c1289 type ii class 2 polyisocyanurate data sheet.

This contributes to its strength high r value and moisture resistance.

Thermomass isomass insulation combines a high performance polyisocyanurate foam core with a multiplex kraft aluminum poly facer.

But like all concrete systems tilt up offers high thermal mass and airtight construction.